Adenso WHM für 200, 300mm und Sonderformatsubstrate

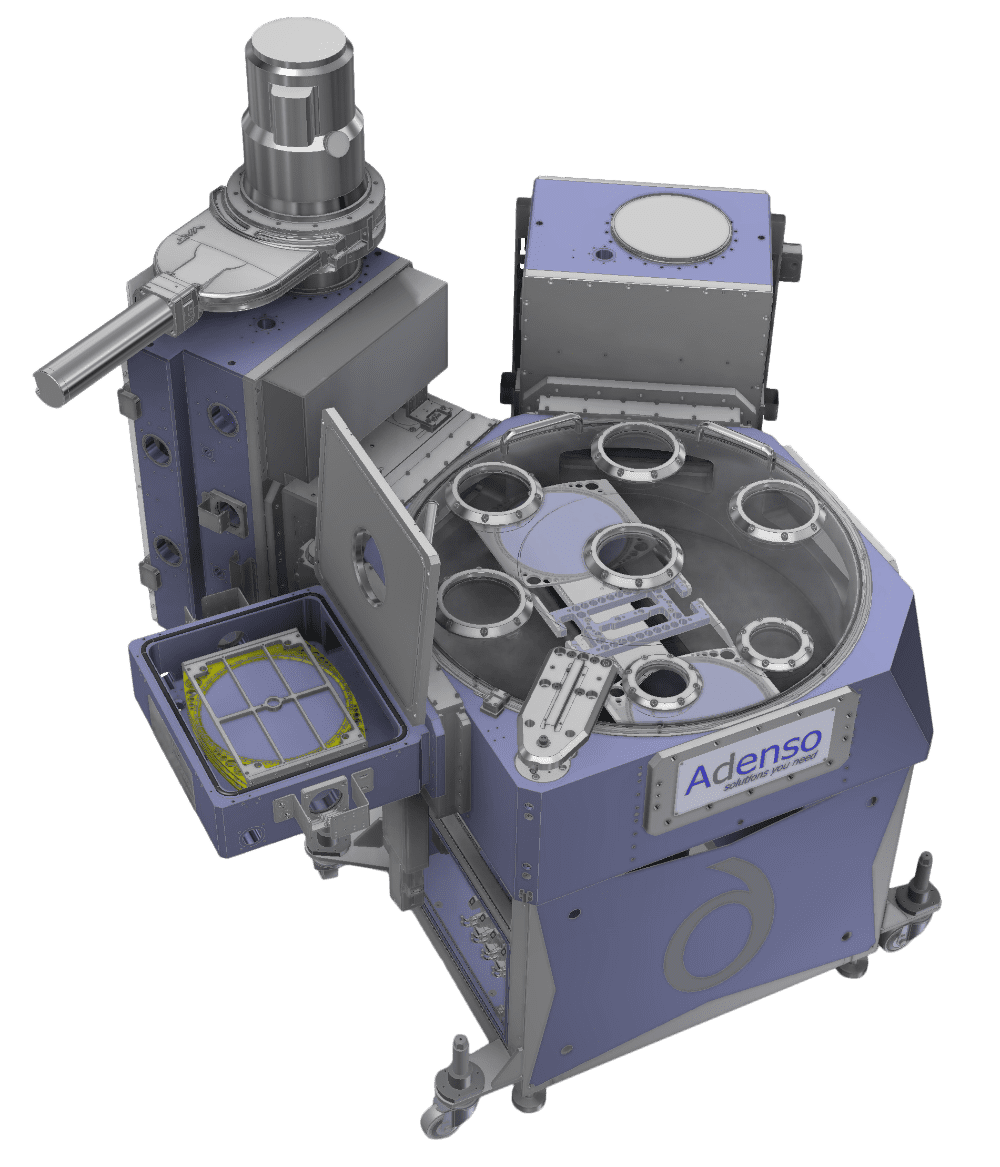

Das von Adenso entwickelte WHM WaferHandling.Module mit einer zentralen Vakuumkammer und integriertem WHR WaferHandling.Robot ist für das Handling von Substraten/Carriern im Hochvakuum optimiert. Unser WHM WaferHandling.Modul arbeitet komplett autark, ist platzsparend und kann vollständig funktionsbereit unkompliziert an Ihre laufenden Prozess-Stationen angedockt werden – fertig ist Ihre Vakuum.Clusteranlage!

- WHR WaferHandling.Robot

- Vakuumkammer mit 4 bis 8 Ports

- LLM LoadLock.Module

- STEALTH.CARRIER

- WAM WaferAlignment.Module

Das Adenso Cluster.Betriebssystem für die Steuerung der VAC.ROBOTICS-Plattform:

zu adControlWHM-VAC-4PS: Das Adenso WHM WaferHandling.Modul für 200mm oder 300mm Wafer mit 4 Ladeports

WHM-VAC-5PS: Das Adenso WHM WaferHandling.Modul für 200mm oder 300mm Wafer mit 5 Ladeports

WHM-VAC-6PS: Das Adenso WHM WaferHandling.Modul für 200mm oder 300mm Wafer mit 6 Ladeports

WHM-VAC-7PS: Das Adenso WHM WaferHandling.Modul für 200mm oder 300mm Wafer mit 7 Ladeports

WHM-VAC-8PS: Das Adenso WHM WaferHandling.Modul für 200mm oder 300mm Wafer mit 8 Ladeports

Robot.Configurator –

Jetzt auf einfache Weise Ihre neue Clusteranlage mit dem ROBOT.Configurator zusammenstellen.

WHR WaferHandling.Robot – die Basis für Handling und Automation

Der Adenso WHR WaferHandling.Robot ist das Herzstück unserer modularen VAC.ROBOTICS Plattform. Der Adenso.WHR übernimmt Handling-Aufgaben von sensiblen und großflächigen Substraten im Bereich VakuumRobotik (Industrial VacBot) und ist für höchste Tragfähigkeit und große Reichweiten optimiert. Die einfache Armgeometrie erlaubt kleine Gateventile und kompakte Handling-Schwenkbereiche.

Ihre Vorteile im Überblick

- REICHWEITE: Größte Verfahrwege – maximale Flexibilität

- NUTZLAST: Höchste Belastbarkeit – unbegrenzte Substratauswahl

- GATE VALVE: Intelligente Kinematik – kleinste Absperrschieber

- FOOTPRINT: Platzsparende Kinematik – kleiner Aufstellraum

- KOMPLEXITÄT: Keep it simple mit Adenso – Sparen Sie Platz und Geld!